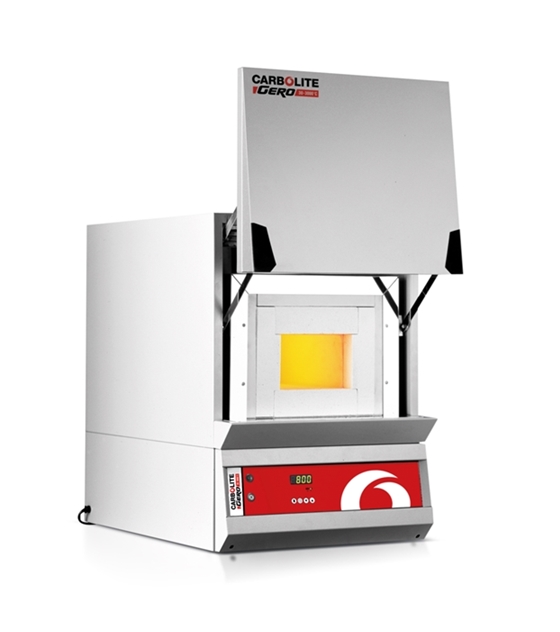

Carbolite GSM Ashing Furnaces

Some analysis techniques may be affected by alumina or silica dust (Al2O3 at SiO2) - the materials normally used to construct furnace chambers. To avoid this, the Carbolite GSM Ashing Furnaces is constructed from a fused quartz material.

Key Features

- 1100°C maximum operating temperature

- Fused quartz furnace chamber, ideal for analyses where Al2O3 or SiO2 could contaminate test results

- Chamber lining offers superior containment of corrosive & aggressive vapours such as H2SO4, HNO3, HCl

This design also offers superior containment of aggressive and corrosive vapours such as sulphuric, nitric and hydrochloric acids by keeping them away from the heating elements.

Additionally if an optional gas inlet is specified, the enclosed design minimises gas leakages from the chamber.

Standard features

- • Moulded ceramic fibre door plug

- • 4 sided heating (2 sides, roof, hearth)

Options (specify these at time of order)

- • Gas Inlet for modified atmospheres (the fused quartz liner provides improved containment)

- • Sample trays & racks

- • A range of sophisticated digital controllers, multi-segment programmers and data loggers is available. These can be fitted with RS232, RS485 or Ethernet communications

- To order contact us via:

Phone: Call +44 (0)330 088 0560 - Email: [email protected]

- Web Form: Get a quote

| Models |

|

|---|