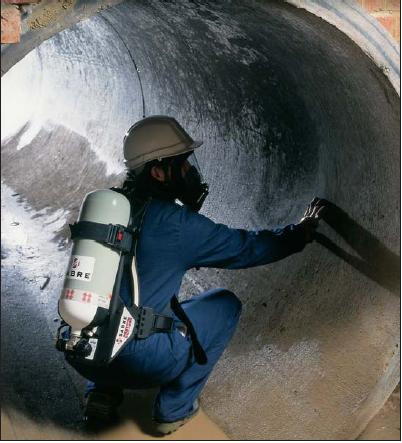

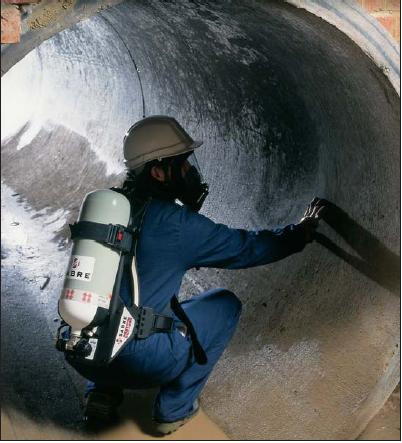

The 3M Contour 100, in combination with the

Vision 3 facemask, offers wearers and specifiers new

levels of comfort, improved fields of vision, true

operational flexibility and low cost, simple

maintenance in a self contained breathing apparatus

that fully reflects 3M's stated philosophy:

to produce equipment that our customers will wear

by choice, not just by necessity.

BACKPLATE

AND

HARNESS

The ergonomic injection

moulded composite backplate

is the heart of the 3M

Contour 100.

The lightweight

webbing harness ensures

optimal load distribution,

balance, comfort and reduced

wearer fatigue.

PNEUMATIC

SYSTEM

The simple, fail safe, spring

loaded piston reducer is fully

serviceable and offers low

service and maintenance

costs.

All hose connections

features 3M's simple and

proven U-clip/O-ring design,

which is very reliable and simple to maintain. Different

high and medium pressure

hose connections ensure

foolproof assembly.

The robust, luminous

pressure gauge and the

whistle feature swivel hose

fittings are shoulder mounted

for easy wearer reference.

DOWNLOADS

Product Literature

Product Literature (Spanish)

Manual

Spare Parts List

Product Datasheet

|

FACEMASKS

The 3M Contour 100 is

designed for use with either

the Vision 3, PanaSeal or

PanaVisor facemasks.

3M

masks are manufactured from

non dermatitic materials and

feature 3M's side mounted

demand valve and front

speech diaphragm.

DEMAND VALVE

The Tempest automatic

positive pressure demand

valve features low breathing

resistance and unsurpassed dynamic performance;

particularly at high flow rates.

The compact, low profile

shape minimises snag

hazards, with the bayonet

fitting being simply

connected and featuring a

safety locking catch.

A true bypass facility

simplifies checking and

donning procedures and

ensures fail safe operation.

The 3M Tempest demand

valve is fully user serviceable

and offers low maintenance

and servicing costs.

PART NUMBERS

1045573 CTR-100 Contour self contained breathing apparatus for single cylinder use, comprising light weight anti-static

composite backplate with Kevlar cylinder band and fully adjustable unpadded body harness,

Two stage pneumatic system comprising Tempest automatic positive pressure demand valve with bypass,

shoulder mounted pressure indicator and 55 bar warning whistle: first stage pressure reducer with single

high pressure cylinder connector. 1045573 CTR-100 Contour self contained breathing apparatus for single cylinder use, comprising light weight anti-static

composite backplate with Kevlar cylinder band and fully adjustable unpadded body harness,

Two stage pneumatic system comprising Tempest automatic positive pressure demand valve with bypass,

shoulder mounted pressure indicator and 55 bar warning whistle: first stage pressure reducer with single

high pressure cylinder connector.

Harness fabricated from flame retardent 50% Kevlar blend materials and features a half lumber pad.

Apparatus accepts full range of Scott breathing apparatus cylinders from 4 7 to 11 0 litres capacity, 200 or

300 bar.

Apparatus is CE Marked to EN137:2006 Class I

1045575 CTR-110 Apparatus as above except with CEN decontamination attachment. 1045575 CTR-110 Apparatus as above except with CEN decontamination attachment.

1045576 CTR-120 Apparatus as above except with CEN airline attachment 1045576 CTR-120 Apparatus as above except with CEN airline attachment

2007104 2007104 Apparatus as above except with Foster/HansenMil Spec airline attachment (CTR-120 Foster/hansen mil

spec) 2007104 2007104 Apparatus as above except with Foster/HansenMil Spec airline attachment (CTR-120 Foster/hansen mil

spec)

2015848 2015848 Apparatus as above except with Hansen HK airline attachment (CTR-120 Hansen HK) 2015848 2015848 Apparatus as above except with Hansen HK airline attachment (CTR-120 Hansen HK)

|

![]() 1045573 CTR-100 Contour self contained breathing apparatus for single cylinder use, comprising light weight anti-static

composite backplate with Kevlar cylinder band and fully adjustable unpadded body harness,

Two stage pneumatic system comprising Tempest automatic positive pressure demand valve with bypass,

shoulder mounted pressure indicator and 55 bar warning whistle: first stage pressure reducer with single

high pressure cylinder connector.

1045573 CTR-100 Contour self contained breathing apparatus for single cylinder use, comprising light weight anti-static

composite backplate with Kevlar cylinder band and fully adjustable unpadded body harness,

Two stage pneumatic system comprising Tempest automatic positive pressure demand valve with bypass,

shoulder mounted pressure indicator and 55 bar warning whistle: first stage pressure reducer with single

high pressure cylinder connector.![]() 1045575 CTR-110 Apparatus as above except with CEN decontamination attachment.

1045575 CTR-110 Apparatus as above except with CEN decontamination attachment.![]() 1045576 CTR-120 Apparatus as above except with CEN airline attachment

1045576 CTR-120 Apparatus as above except with CEN airline attachment ![]() 2007104 2007104 Apparatus as above except with Foster/HansenMil Spec airline attachment (CTR-120 Foster/hansen mil

spec)

2007104 2007104 Apparatus as above except with Foster/HansenMil Spec airline attachment (CTR-120 Foster/hansen mil

spec)![]() 2015848 2015848 Apparatus as above except with Hansen HK airline attachment (CTR-120 Hansen HK)

2015848 2015848 Apparatus as above except with Hansen HK airline attachment (CTR-120 Hansen HK)